Understanding the Role of Natural and Hydromechanical Resonant Frequencies in Hydraulic Systems

The understanding of natural frequency and hydromechanical resonant frequency is crucial in the design and operation of hydraulic systems.

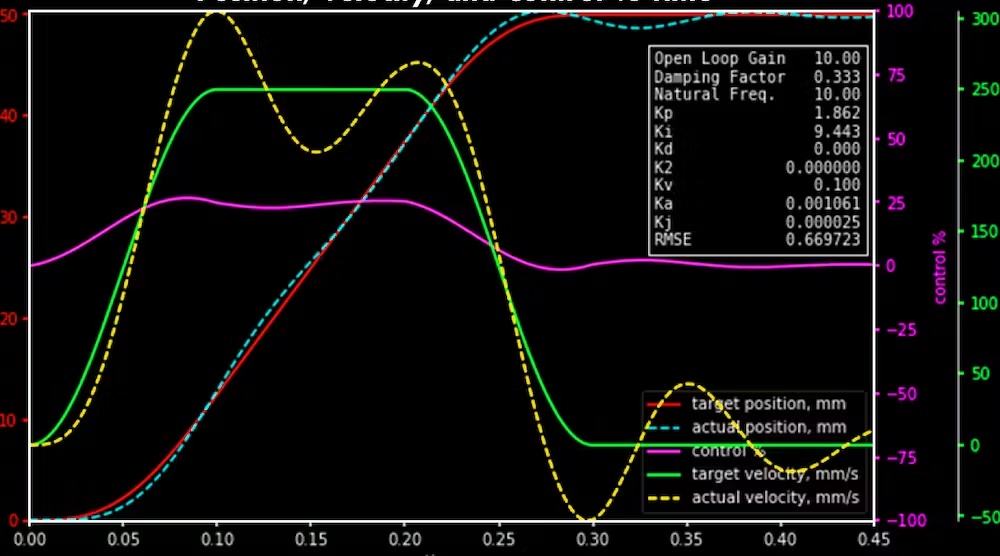

Natural frequency refers to the stiffness of a hydraulic system. Systems with a higher natural frequency are easier to control when accelerating quicker than systems with a low natural frequency. A hydraulic cylinder can be modeled as a mass between two springs. Systems with a low natural frequency have a low spring constant relative to the mass of the load, while systems with a high natural frequency have a high spring constant relative to the load mass. The natural frequency should ideally be at least four times the required frequency of acceleration. This is particularly true when using a standard hydraulic motion controller. The natural frequency is calculated from the mass of the load, the areas of both the rod- and cap-end of the piston, and the bulk modulus of the hydraulic fluid.

On the other hand, the hydromechanical resonant frequency (HRF) of a valve-cylinder circuit is an important value to know. If a cylinder is stroking, and its control valve suddenly shifts to block flow, the cylinder and its load will vibrate, usually with considerable noise and sometimes with considerable violence. This is HRF in action. The noise arises from the resonance that exists when the kinetic energy of the load mass and the potential energy stored in the hydraulic fluid’s compressibility are exchanged. The HRF can be estimated using a formula that takes into account the average wetted area of the two sides of the piston, the fluid compressibility factor or bulk modulus, the effective mass acting at the end of the cylinder rod, and the cylinder’s effective stroke length.

Understanding these frequencies is crucial to the smooth, reliable operation of any hydraulic circuit. They establish the maximum rate at which a hydromechanical system can be cycled, which dictates manufacturing productivity and, consequently, product cost. Advanced electrohydraulic motion controllers can perform well when the ratio of the natural frequency to frequency of acceleration is less than four, allowing for the use of smaller components and resulting in cost savings. However, it's important to note that attempting to cycle a machine faster than its resonant frequency can lead to failure, noise, and damage. Therefore, calculating these frequencies should be a routine part of any design procedure.

Labels: hydraulic system design

June 26, 2023

Return to List