Parker Hannifin Plc

Product Training

Hydraulic Fluids

And Contamination

Level 1

Hydraulic Fluids

Mineral Oils

Environmentally

Friendly Oils

Fire

Resistant Oils

Hydraulic Fluids

Mineral Oils

Environmentally

Friendly Oils

Fire

Resistant Oils

Level 1

Hydraulic Training

Hydraulic Fluids and Contamination

List of Figures

Figure

Page

1.1

The three main hydraulic oil groups…………………………………….. 4

3.1

Viscosity index graph……………………………………………………… 7

6.1

Photomicrograph of particle contamination……………………………. 13

6.2

ISO 4406 21/19/17 fluid photomicrograph………………………………13

6.3

ISO 4406 16/14/11 fluid photomicrograph………………………………13

Ref H F&C L1 0504

2

Level 1

Hydraulic Training

Hydraulic Fluids and Contamination

Contents

List

of

figures

3

1.0

Introduction

4

1.1

What is a hydraulic fluid?

4

2.0

Oil

Types

5

2.1

Mineral

Oils

5

2.1.1

ISO

Classification

5

2.2

Fire

Resistant

Oils

5

2.2.1

ISO

Classification

6

2.3

Environmentally

Friendly

Oils

6

3.0

Main Properties of Hydraulic Oils

7

3.1

Viscosity

7

3.2

ISO

Viscosity

Grades

8

3.3

Oxidation

Stability

8

3.4

Lubricity 8

3.5

Pour

Point

8

4.0

Fluid Care and Maintenance…………………………………..9

5.0 Contamination………………………………………………….10

5.1 Filtration…………………………………………………………10

5.1.1 Suction Line Filters…………………………………………….10

5.1.2 Pressure Line Filters……………………………………..……10

5.1.3 Return Line Filters……………………………………………..11

6.0 Oil

Contaminant………………………………………………..11

6.1 Contaminant

Measurement…………………………………..12

7.0

Other Forms of Contaminant………………………………...14

7.1 Water……………………………………………………………14

7.2 Air………………………………………………………………..14

Summary Points………………………………………………………..15

Ref H F&C L1 0504

3

Level 1

Hydraulic Training

Hydraulic Fluids and Contamination

1.0 Introduction

Level One training has been devised as a ‘self teach’ module for persons who have

no, or very little, prior knowledge of the subject matter. The aim is for persons to

work through the information provided at their own pace and in their own time.

When they have completed the module and feel confident that they have increased

their knowledge they can complete a test that accompanies the module. Successful

completion of the module test permits progress onto Level Two.

1.1 What is a hydraulic fluid?

A hydraulic fluid is something that is used to transmit a force in order to create the

movement of an actuator, which results in useful work being done. It is something

that is used to cool. It is something that is used to lubricate. It is something that has

little or no compression. It is something that can take up any shape.

Water, mineral oils, vegetable oils, water and oil mixtures, oil and water mixtures,

water and glycol mixtures and man made synthetic oils are all examples of hydraulic

fluids. In this module we will consider some of these fluids and relate them to typical

applications where they are to be found. Generally, hydraulic oils fall into three main

groups as shown in figure 1.1.

Hydraulic Fluids

Fire

Resistant Oils

Environmentally

Friendly Oils

Mineral Oils

Figure 1.1 – The three main hydraulic oil groups

The International Standards Organisation (ISO) classifies oil according to its

composition and properties, and uses a letter coding system to identify the oil type.

These are outlined briefly in the following chapter.

Ref H F&C L1 0504

4

Level 1

Hydraulic Training

Hydraulic Fluids and Contamination

2.0 Oil Types

2.1 Mineral Oils

Mineral oils make up one of the largest groups of hydraulic fluids. The vast majority

of mobile and many industrial hydraulic applications employ mineral oils as the

hydraulic fluid. They are relatively inexpensive, widely available and offer a good

range of different viscosity grades. (More on viscosity later). As shown below,

mineral oils come with a range of different properties, which help when selecting an

oil for a particular application. It should be understood however, that these are not

the only considerations to be taken into account when selecting an oil.

The two biggest disadvantages of a mineral oil are;

its ability to burn, (flammability)

its increase in viscosity at higher pressures.

These two factors preclude the use of mineral oils in hazardous environments and in

systems operating at high pressures. (1000 bar and over)

2.1.1 ISO Classification

ISO Type

Composition and properties

Ref H F&C L1 0504

HH

Refined mineral oil – non inhibited (base oil with none of the

properties listed below)

HL

Refined mineral oil with anti rust and anti oxidation properties

HM

A HL type oil but with anti wear properties

HR

A HL type oil with improved viscosity temperature properties

HV

A HM type oil with improved viscosity and temperature properties

HS

Synthetic fluids containing no specific fire resistant properties

2.2 Fire Resistant Oils

Hydraulic equipment used in working environments where the occurrence of a fire

would lead to an extremely dangerous situation arising almost instantly, generally

use a fire resistant hydraulic fluid. Such environments can be found in coalmines,

off shore oil platforms, some areas of the marine and shipping industry, injection

moulding etc. The main criterion of fire resistant oil is that it will not support a flame.

In other words, it will not readily burn if it comes into contact with a flame or hot

surface. Just imagine the devastating effect of burning oil and the fumes this would

create down a coalmine for example.

One of the main disadvantages of oil water mixtures is that component lubrication is

not as good as when using mineral oil. System pressures are usually lower due to

the de-rating (lowering) of component specifications. Maximum operating

temperatures are typically lower than those encountered with mineral oils, and part

corrosion resistance is lower.

5

Level 1

Hydraulic Training

Hydraulic Fluids and Contamination

Man-made synthetic fire resistant fluids are available, for example phosphate esters,

but the cost of these fluids limits the number of applications where they are found.

Typically, applications such as plastic injection moulding and die casting, where the

presence of hot surfaces pose a high fire risk, may well use this type of hydraulic

fluid. Their lubrication characteristics are very good, (similar to mineral oils), but

great care needs to be taken to ensure the compatibility of component seals and

hose materials with these fluids.

Some of the main types of fire resistant fluids in use are listed below.

2.2.1 ISO Classification

ISO Type

Composition and properties

Ref H F&C L1 0504

HFAE

This is high water base oil, sometimes referred to as an ‘oil in water’

emulsion. The maximum oil content does not exceed 20%, ensuring

that the water content is always 80% or greater.

HFB

This is a 60% oil 40% water mixture, known as a ‘water in oil’ or

invert emulsion.

HFC

This is a water glycol mixture – a water polymer solution, developed

for use in the aircraft industry. Water content can be between 35%

and 80%.

HFDR

Manmade synthetic fluid - phosphate ester type. Contains no water

2.3 Environmentally Friendly Oils

With the increased awareness regarding ‘green’ issues and protection of the

environment, a whole group of environment friendly oils are available on the market.

Biodegradable synthetic oils and vegetable oils form part of this group. They are

typically used where the possibility of leakage from a hydraulic system, for example

due to a hose failure, would pose a serious environmental problem. Some

manufacturers of grass cutting machinery and even manufacturers of town center

precinct cleaners and sweepers may use these types of oils. Some of these oils

offer a performance equivalent to the standard ISO mineral oils, however, great care

has to be taken with the selection of seal and hose materials when using these

products.

6

Level 1

Hydraulic Training

Hydraulic Fluids and Contamination

3.0 Main Properties of Hydraulic Oils

N.B Only the main points are covered at this level.

3.1 Viscosity

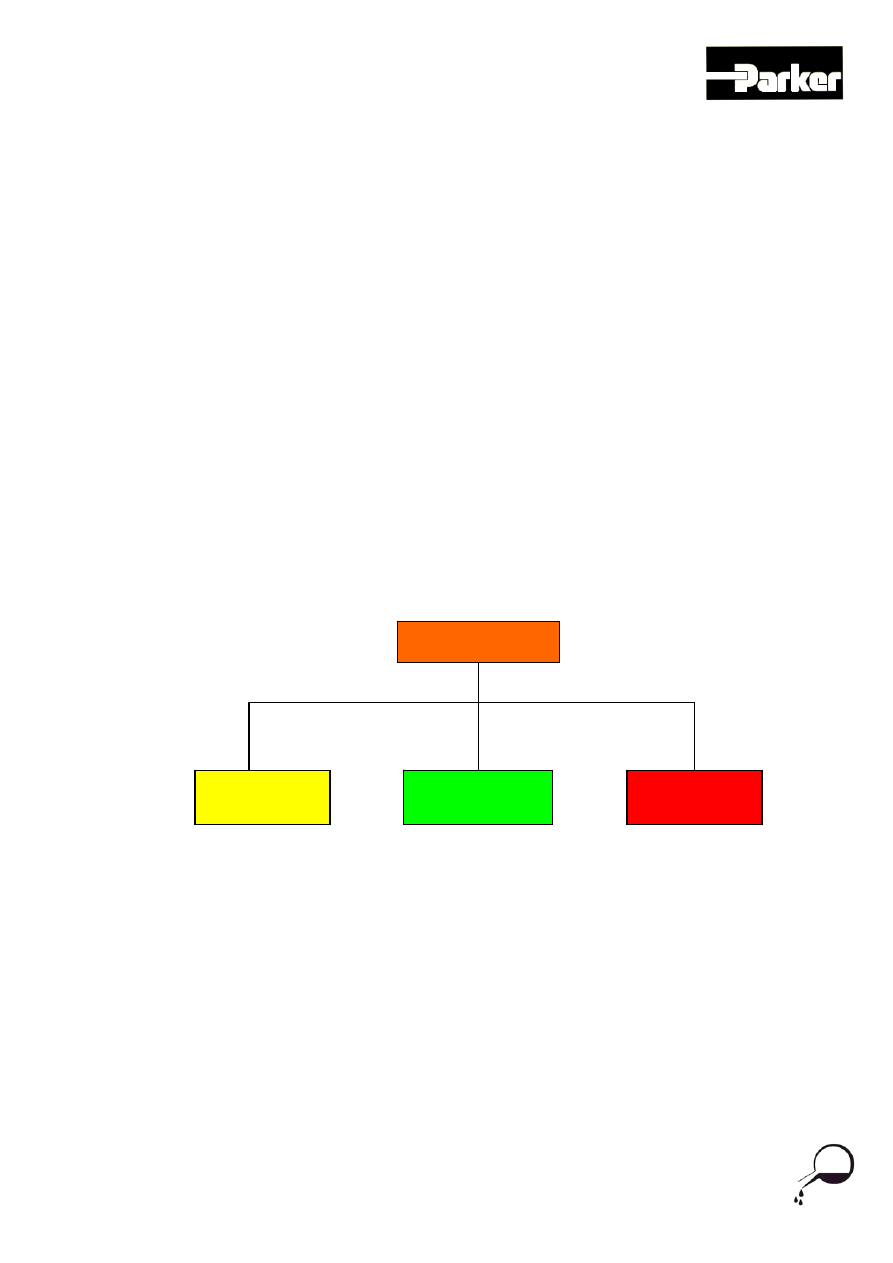

Viscosity is arguably the most important factor a manufacturer has to consider when

selecting an oil for a hydraulic system. Viscosity is a measure of an oils resistance

to flow. A fluid with a low viscosity, cooking oil for example, flows easily at room

temperature, whereas a fluid with a high viscosity, treacle for example, does not.

In section 1.1 it was mentioned that an oil has to fulfil several different requirements.

Not least of these is its ability to lubricate and maintain a lubricant film between

moving parts. This ability has to be maintained across a range of temperatures and

differing environmental conditions. An oil which loses it’s viscosity at a higher

temperature would leak away too readily through clearances in valves and pumps

and cause a breakdown of the lubricating film. This in turn would lead to excessive

wear of components and introduce contaminant into the hydraulic system.

Conversely, an oil who’s viscosity increases too greatly in a cold environment will

again be unable to offer correct lubrication and have a tendency to block or restrict

flow through small orifices and cause sluggish operation of machinery. Machinery

operating over wide temperature range will be fitted with coolers and heaters as

required, in order to help stabilise the system temperature as much as possible.

However, the most critical time period for damage to be caused is after initial start

up before any such conditioning equipment can come into effect. To help counter

this problem, most hydraulic oils have an improved viscosity index additive. This

additive helps to maintain the stability of an oil’s viscosity and allows it to perform

correctly over a wider temperature range before the use of conditioning equipment

becomes necessary. Figure 3.1 shows the difference between oils with different

viscosity indexes.

Ref H F&C L1 0504

Viscosity

0 20

40

60

80

100

120

Temperature

°C

Low VI oil

High VI oil

Figure 3.1 – The viscosity of oil with a higher viscosity index changes less over

the temperature range. (Blue line oil is more stable than the red line oil).

7

Level 1

Hydraulic Training

Hydraulic Fluids and Contamination

3.2 ISO Viscosity Grades

The Society of Automotive Engineers (SAE) and the International Standards

Organisation (ISO) have each established their own way of defining an oils viscosity

range. For our purpose we will only consider the ISO grading system.

The ISO viscosity classification uses the centiStoke (cSt) as its unit of measure and

relates to the viscosity of an oil at 40 degrees C. The grade scale is split into

eighteen viscosity levels ranging from 1.98cSt to1650cSt. The mid point of each

level, to the nearest whole number, defines the viscosity grade. ISOVG 22, ISOVG

32, ISOVG 46, ISOVG 68, ISOVG100 are examples of the different grades. The

bigger the ISO number, the higher the viscosity of the oil.

3.3 Oxidation Stability

Oxidation of oil is the result of the oils reaction with the oxygen in the air of the

reservoir. Excess heat, water, aeration of the oil and foaming can all lead to

increased oxidation of the oil. Once the levels of oxygen increase, the service life of

the oil is seriously reduced. Varnishes and sludges are formed which effect the

operation of valves and spools and can even block orifices. The addition of an

oxygen stabiliser in the oil helps to overcome these problems. A good hydraulic

system however, where temperatures are controlled, return lines are correctly sized,

and reservoir internal layout is correct will all help to keep the levels of oxygen

lower.

3.4 Lubricity

Good quality hydraulic fluid will have good lubricity in order to prevent undue friction

and wear between moving parts. Due to the extremely small clearances between

moving components in pumps, motors, valves and actuators an oil must be able to

maintain a good level of lubrication when being forced out of these clearances. For

this reason most quality hydraulic oils contain anti-wear additives, which help to

reduce wear and provide adequate lubrication.

3.5 Pour Point

The lowest temperature at which a fluid begins to congeal is known as the pour

point. It is vital therefore that when specifying an oil for a particular machine the

pour point must be 10 to 20 degrees C lower than the lowest anticipated operating

temperature of the machine. If not, flow of oil to the pump will be possible.

Ref H F&C L1 0504

8

Level 1

Hydraulic Training

Hydraulic Fluids and Contamination

4.0 Fluid Care and Maintenance

Manufacturers and users of hydraulic equipment can save themselves much time

and money by adhering to some simple rules and employing good practices when it

comes to looking after and using hydraulic oils. Downtime and component failure

can be reduced or eliminated completely.

Drums of oil should always be stored on their sides. This prevents the build up of

water that is common when they are stored on end. Water can find its way into the

drum when the cap is removed or left loose.

Always transfer oil from a drum to a reservoir by a sealed filling system, which

incorporates a filter in the line to clean the oil to the required system cleanliness

level. Many people think that new oil from a drum is clean. This is not the case.

Connections on the drum and reservoir should be self-sealing and be easy to clean

before connection is made.

Always ensure that oil storage areas are kept clean and that dirt and grime is not

allowed to build up.

Prevent the build up of heat in an oil, which will help to keep the amount of oxidation

to a minimum and also reduce other associated problems.

Ref H F&C L1 0504

9

Level 1

Hydraulic Training

Hydraulic Fluids and Contamination

5.0 Contamination

Oil contamination is the downfall of any hydraulic system. Over eighty percent of

hydraulic pump failures occur as a result of oil contamination.

Contamination causes problems in a system because it interferes with the hydraulic

fluids four main functions.

To act as a medium for transmitting energy

To lubricate internal moving parts

To act as a heat transfer medium

To seal clearances between close fitting parts

The lower limit of visibility of a human eye is approximately 40 microns. In other

words, the average person can see dirt which measures 40 micron and larger. This

means that just because oil looks clean it does not necessarily follow that it is clean.

Most of the harmful dirt and contaminant in a hydraulic system is smaller than 40

microns.

Each time a cylinder is extended and the retracted a thin layer of dirt is sucked back

in to the system. The surrounding atmosphere is of prime importance when looking

at the cleanliness of a system. On modern industrial hydraulic valves clearances

between moving parts are in the region of 3 to 6 microns. To give an insight into the

sizes mentioned, a human hair is approximately 70 microns in diameter and a grain

of salt is in the region of 100 microns.

5.1 Filtration

Apart from following good practices with regard to the storage and handling of

hydraulic fluids, good system filtration is a prerequisite in the fight against

contamination and prolonging system component life. There are three main types of

filter that can be used in the average hydraulic system. Some systems use all three,

whilst others may only use one or two. Only a very brief outline of each typical filter

type will be discussed in this module.

5.1.1 Suction line filters

Used more on mobile hydraulics, these types of filters are becoming less popular.

Due to the filters location, in the bottom of the reservoir before the suction line, the

maintenance of this item tends to be poor. Consequently, they are usually only

examined when a problem occurs. Once the filter begins to block pump cavitation is

the likely result due to lack of oil at the pump inlet. Destruction of the pump usually

follows.

5.1.2 Pressure line filters

This type of filter is placed within the hydraulic system after the pump. They are very

efficient in operation and can be placed to protect certain delicate component parts.

They are designed to cope with high-pressure peaks within the system. Because of

this, the filter housing is of a heavier more robust construction, which consequently

makes them more expensive. The filter elements however have the advantage of

being able to handle large oil flows and filtering it down to very fine micron sizes; 3-4

microns.

Ref H F&C L1 0504

10

Level 1

Hydraulic Training

Hydraulic Fluids and Contamination

5.1.3 Return line filters

A return line filter is placed in the circuit just before the reservoir. Placed in this

position it traps any dirt that has been introduced into the system before it is

returned back in to the hydraulic reservoir. It has the advantage of working in a

lower pressure area of the system and can therefore the element housing can be

made from lighter section material than a pressure filter. Care has to be exercised

when selecting return line filters as some system components can be affected by the

return line backpressure build up.

6.0 Oil Contaminant

Solid contaminant is always present in hydraulic systems. It can range in size from

sub-micron to clearly visible particles; 40 microns and above. The smaller the

particles, the more numerous they tend to be. Not all particles are significant in

promoting wear in a contact area. Generally, large particles are not the ones

promoting further ware, as they are too large to enter between component

clearances. Similarly, particles that are significantly smaller than component

clearances are able to pass through without interaction with the surfaces.

The contaminant size causing the most damage in a hydraulic system is the hard

particle of approximately the same dimensions as the component clearances. These

particles are trapped in the contact area between the components and are dragged

under pressure across the surfaces. This continual wearing and scratching of these

surfaces, causes component material to break off and enter the system. If filtration

is poor, these ‘new’ contaminant particles will cause further wearing of component

parts as they move around the system. In other words the damage becomes self-

perpetuating until the point is reached where system efficiency is greatly reduced or

component failure occurs. Many components in mobile and industrial hydraulic

systems have clearances in the range of 2 to 15 microns.

There are a number of different methods of establishing the solid contaminant

content of a fluid. These include manual counting, via a microscope, to a range of

automatic counters. Some of these can be installed in-line or on-line but this is an

expensive option. The most common method is to take a sample from the system

and evaluate the cleanliness on a remote particle counter. Special precautions must

be taken to ensure that accurate results are obtained from this process. Super clean

pre-flushed sampling bottles and suitable sampling points must be used to ensure a

representative sample is obtained and it is not further contaminated prior to

inspection. This is a specialized procedure and is best carried out by specially

trained personnel.

Ref H F&C L1 0504

11

Level 1

Hydraulic Training

Hydraulic Fluids and Contamination

6.1 Contaminant Measurement

Once oil samples have been obtained and evaluated, it is usual to express the

cleanliness of the system by reference to a solid contaminate code, such as ISO

4406. ISO 4406 solid contamination codes are expressed as three numbers

separated by a diagonal oblique, e.g. ISO 4406 - 18/16/13.

These figures represent coded ranges giving the number of particles greater than a

specific size. The numbers refer to the number of particles greater than 4 microns, 6

microns and 14 microns respectively. The ISO 4406 range number codes are given

below:-

Number of particles per 100 mls of fluid

Code

Number

of

particles

24-

8,000,000

16,000,000

23-

4,000,000

8,000,000

22

-

2,000,000

4,000,000

21

-

1,000,000

2,000,000

20

-

500,000

1,000,000

19

-

250,000

500,000

18

-

130,000

250,000

17

-

64,000

130,000

16

-

32,000

64,000

15

-

16,000

32,000

14

-

8,000

16,000

13-

4,000

8,000

12-

2,000

4,000

11-

1,000

2,000

10-

500

1,000

9-

250

500

8

-

130

250

7-

64

130

6-

32

64

5-

16

32

4-

8

16

3

-

4

8

2-

2

4

1-

1

2

Ref H F&C L1 0504

12

Level 1

Hydraulic Training

Hydraulic Fluids and Contamination

The introduction of the 3 number code is relatively new. The previous convention

was to report a two-figure code representing the numbers of particles greater than 5

microns and 15 microns only.

The introduction of the 4-micron level reflects concern over more modern equipment

containing components with finer tolerances. Generally the cleaner the system the

better, but as achieving higher cleanliness standards means using finer filters which

will reach capacity more quickly, an economic balance results between cost of filters

and protection of the other system components.

The optimum cleanliness to achieve this balance will depend on the needs of the

system components and the nature of the operation. For relatively unsophisticated

systems such as mechanical handling equipment operating at low pressures, this

can be typically 18/16/13. Whereas for complex machine tools and injection molding

equipment containing servo or proportional control valves, the user might aim to

achieve 16 /13/11.

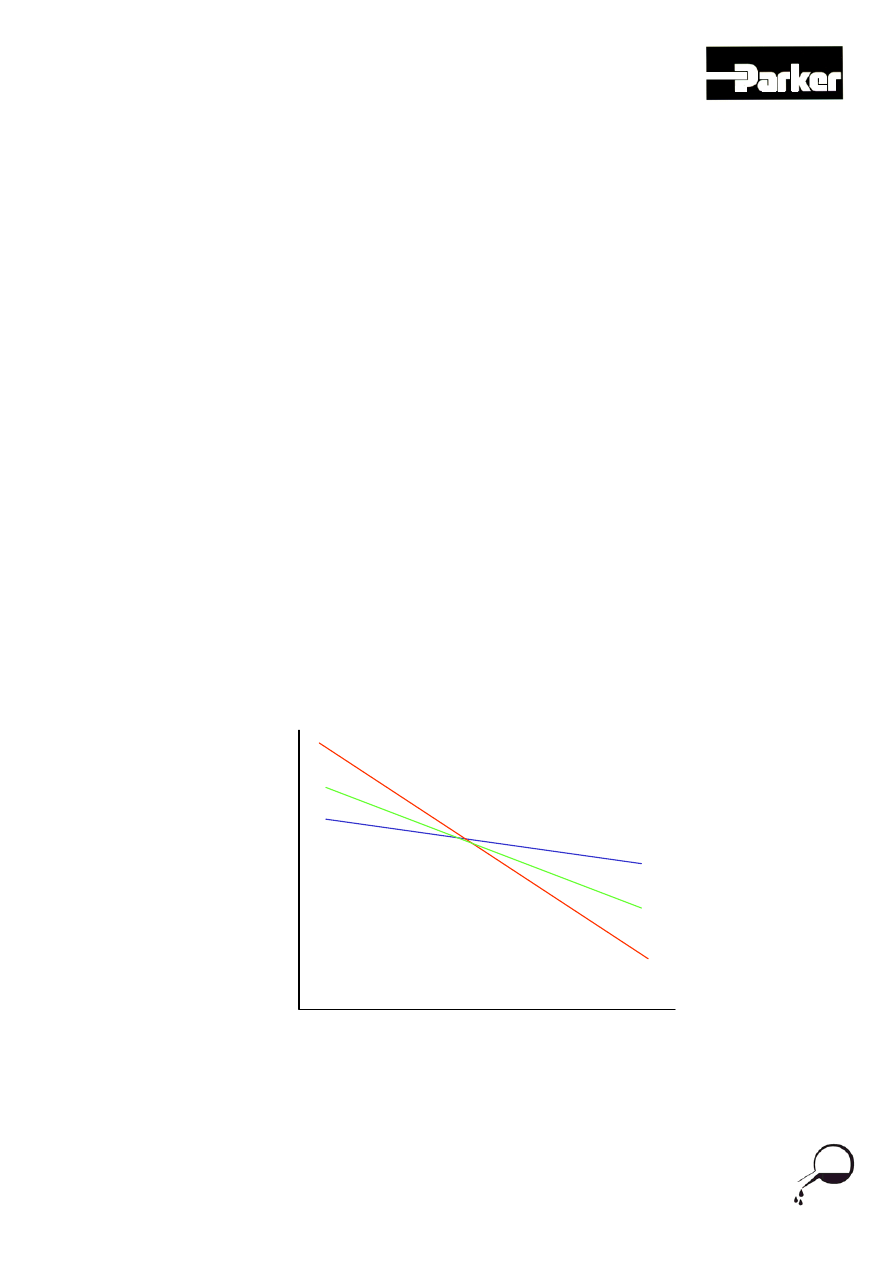

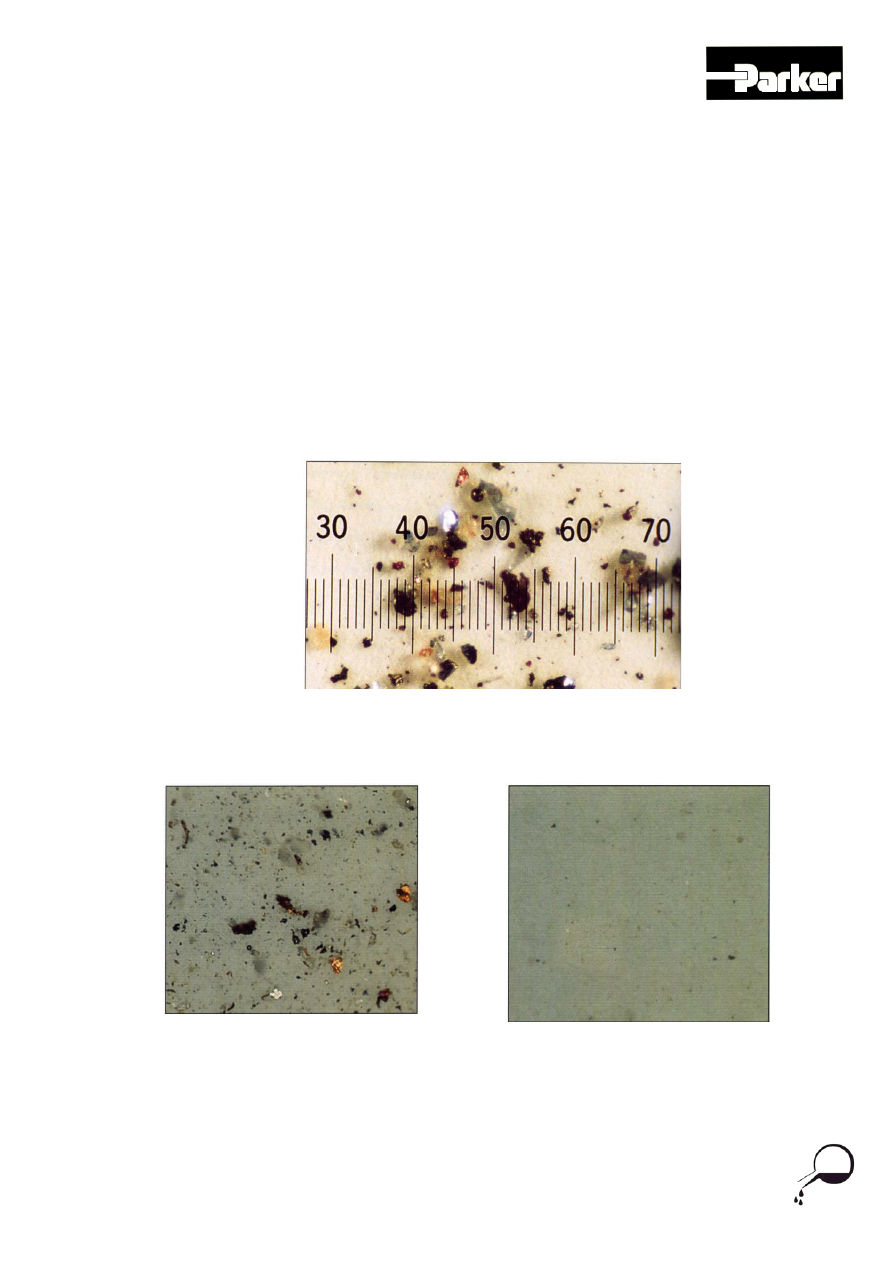

Figure 6.1 - Actual Photomicrograph of particle contamination Scale 1 division = 20

microns

Ref H F&C L1 0504

Fig 6.2 ISO 21/19/17 fluid (Magnification

100x)

Fig 6.3 ISO 16/14/11 fluid (Magnification

100x)

13

Level 1

Hydraulic Training

Hydraulic Fluids and Contamination

7.0 Other forms of contamination

So far we have looked at solid particles as a form of contamination. There are of

course other types of contamination that can cause damage to the pump and other

system components. Two of these (the most common) are discussed below.

7.1 Water

Water usually gets into a system because of condensation. Condensation forms on the

reservoir sides when the system is shut down, possibly over night as the system cools,

and is mixed in with the oil during start up the following morning. This form of

contamination is more common on mobile systems due to the changes in ambient

temperatures during night and day. One of the first signs of water contamination is that

the oil looks cloudy or milky. Condensation can lead to rust forming on the internal

surfaces of pumps and valves which in turn leads to solid particles breaking off and

contaminating the system.

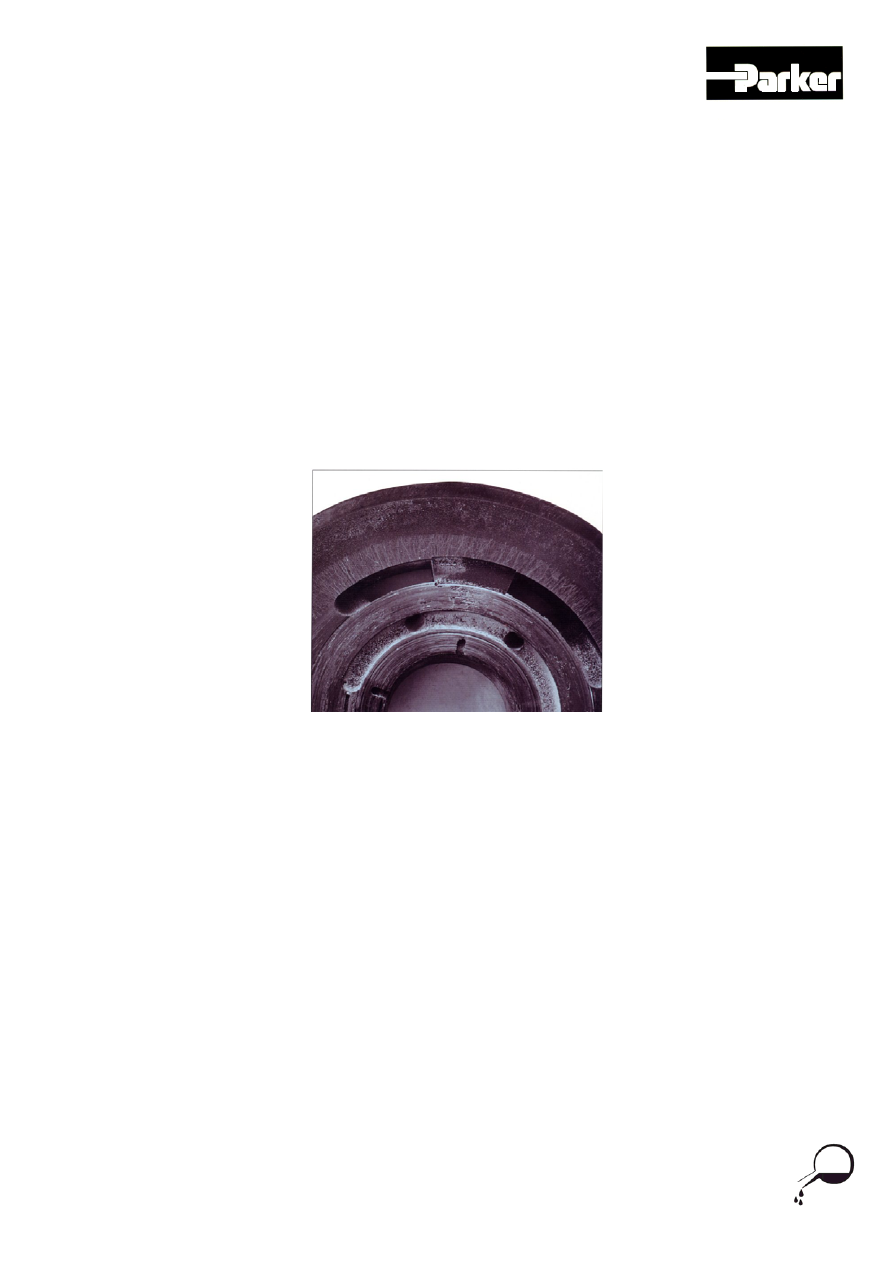

Figure 7.1 – Example of pump wear due to water contamination

7.2 Air

Air is not often thought of as a contaminant, but due to the nature of the oil / air mix it

can be detrimental to all hydraulic components, primarily the pump. Air can enter the

system through loose connections on the suction side of a cylinder or the suction side

of a pump. Air can cause cavitation in a system; cavitation can cause major component

damage in a hydraulic system and can destroy or seriously damage a pump in a matter

of minutes. A hydraulic system running with air in the system can sluggish and erratic

in operation. Air at the pump inlet will be very noisy due to cavitation taking place. The

system oil will show traces of minute air bubbles in the oil reservoir and in serious

cases foam will form on the oil surface in the reservoir.

Ref H F&C L1 0504

14

Level 1

Hydraulic Training

Hydraulic Fluids and Contamination

Ref H F&C L1 0504

15

Summary Points

There are three main groups of hydraulic oils

Mineral oils are the largest and most common group of oils

Mineral fire resistant oils are mixed with water

Man made synthetic oils are expensive compared to mineral oils

Environmentally friendly oils are becoming more prominent in the field

Viscosity measures of the resistance of oil to flow

Viscosity is measured in centistokes

The Pour point of an oil is the lowest temperature that the oil begins to

congeal

More than eighty percent of all hydraulic failures are as a direct result of

contamination

The smallest contaminant is generally the biggest cause of damage due to

the erosion of the small clearances between component parts

Reservoirs should be filled with oil which has passed through a sealed pre-

filling filtration system

Filters generally fall into three categories: suction, pressure and return